In the demanding world of industrial coatings, wear resistance is a critical factor for extending the life of components in oil & gas, pulp and paper, and heavy machinery applications. At DuraTech Processes Inc., we specialize in mid-phosphorus electroless nickel (EN) plating—typically 6–9% phosphorus content—and its composite variants like our flagship Durabide®, which incorporates ultra-hard silicon carbide (SiC) particles. One of the most effective ways to boost the performance of these coatings is through post-plating heat treatment. In this post, we’ll explore how heat treatment dramatically increases hardness and enhances abrasion resistance, backed by industry-standard testing.

EN Plating Hardness Improves with Heat Treatment

As-plated mid-phos EN offers good initial hardness, typically in the range of 500–650 HV (Vickers hardness) or about 45–57 HRC. This provides solid corrosion protection and moderate wear resistance right out of the bath.

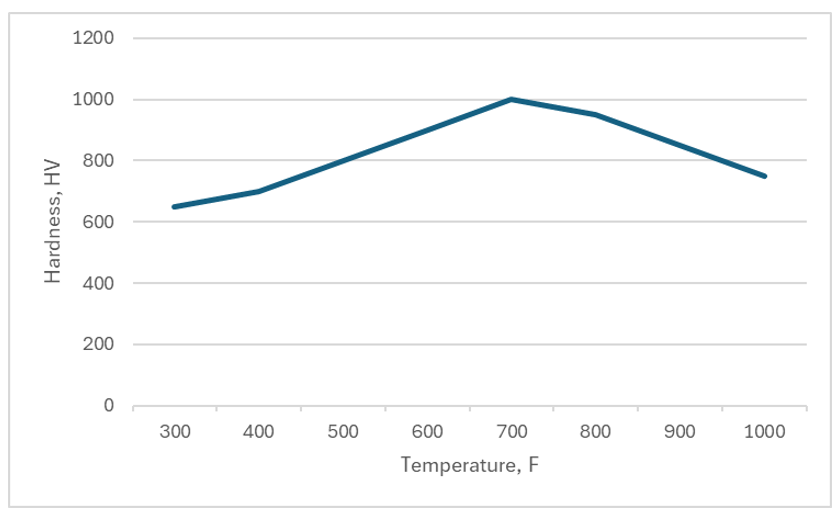

However, heat treatment triggers precipitation hardening by forming nickel phosphide (Ni₃P) phases in the amorphous matrix. The effect is temperature-dependent:

- At 400°F (204°C): Often used for stress relief or hydrogen embrittlement removal, this yields a modest boost to 600–750 HV.

- At 700°F (371°C): Approaching peak conditions, hardness can reach 900–1100 HV (equivalent to 65–70 HRC), rivaling or exceeding hard chrome in many scenarios.

Effect of Heat Treatment at Different Temperatures on the Hardness of Electroless Nickel

These values make heat-treated mid-phos EN ideal for high-wear environments like pumps, cylinders, and pipelines.

SiC Particles in Durabide Add Hardness & Maximize Results

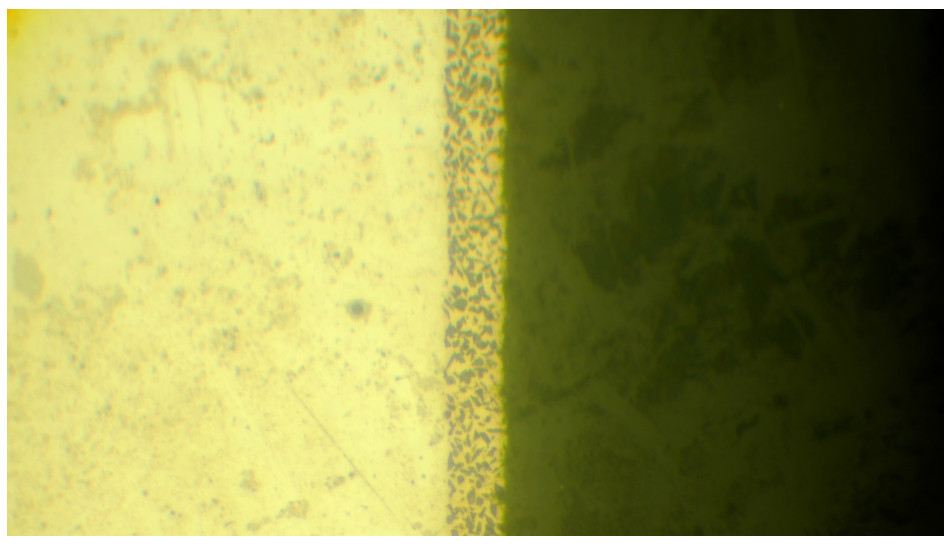

For even greater durability, we embed SiC particles (Vickers hardness 2400–2800 HV) into the nickel matrix. These hard particles bear the brunt of abrasive forces while the hardened nickel provides support and corrosion barrier.

The result? Composite coatings like Durabide® outperform plain EN in real-world abrasion.

Cross section of SiC particles in electroless nickel composite coating

Measuring Abrasion Resistance: The Taber Wear Test

The Taber abrasion test (ASTM D4060) is a gold-standard method for quantifying wear. A specimen rotates under loaded abrasive wheels and wear is measured by weight loss per 1,000 cycles. Heat-treated mid-phos EN shows significantly lower wear indices—often 50–70% less material loss compared to as-plated. When combined with SiC composites, Taber results improve further, with minimal weight loss even after thousands of cycles, making it superior for abrasive slurries or plunger-on-barrel contact in oilfield applications.

Why Choose Heat-Treated Composite EN from DuraTech?

At DuraTech, our oversized tanks (up to 40 ft) and in-house heat treating allow us to deliver uniform, high-performance coatings tailored to your needs. Whether you’re replacing hard chrome for environmental reasons or seeking longer part life, heat-treated Durabide® offers proven hardness and abrasion resistance.

Ready to maximize your components' durability?

for a consultation or sample testing.